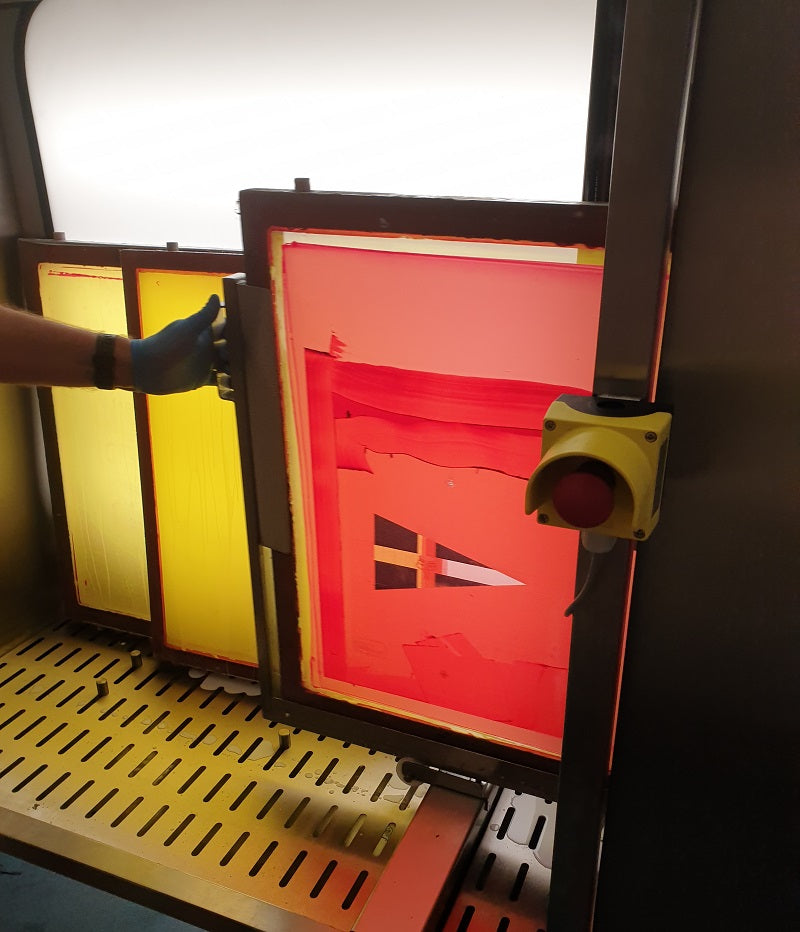

Next-Level Customisation

At Banana Moon, we pride ourselves on offering an unparalleled range of unique processes and services that elevate your custom clothing and merchandise to the next level. Our expertise and creativity allow us to bring your vision to life with precision and style.